How to hold your own in the garden.

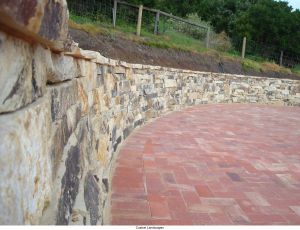

Anyone who landscapes will need a retaining wall somewhere in a garden.

If you have a flat block, beds can be raised to add interest, and save your back.

If you have a sloping block, it may be necessary to keep your neighbours garden out of yours, or, keep your garden in its place.

Dry stone and retaining walls can range from simple edging delineating boundaries to engineered walls that physically hold back soil and stabilise a site.

Whatever the circumstances, the appearance of the structure can be as important as the function of the wall.

Stone was probably the first material used for retaining and is still the most attractive and natural product for this use. It is a most environmentally friendly product, not subject to rotting, white ants or fire and has a low embodied energy.

Where a wall is over a metre high, it is subject to legislative requirements which will specify the manner in which it is to be built.

Anything below a metre can be dry stacked, or laid with mortar.

Footings are optional depending on factors such as; the substrate, the height of the wall and the degree of retaining required. Walls can be upright or reclining.

Drainage can be a simple weep hole (in a mortared wall) to more sophisticated systems with water proof sheeting, ag drain (slotted drain pipes) and gravel backfill.

Do not use reactive back fill (clay) because the constant swelling and shifting can push the walls over.

Basket Range Sandstone produces Random walling stone and Sawn walling stone.

Random, as its’ name suggests, is stone pulled out of the quarry in varying shapes and sizes, usually about the size of a soccer ball. These are fitted together with mortar to give a rustic look. If more care is taken to select stones with flat tops and bottoms with a squarish look then a lovely dry stack wall of all different height stones can be laid.

The Sawn Wallers are stone masonry made easy. Each stone is sawn top and bottom to a set height and are then laid butting to the next stone. The more adventurous can incorporate a combination of stone sizes which are multiples of the lowest height. This system need not include a mortar bed but this depends on various factors.

Another technique experiencing a resurgence in popularity is using gabion baskets. Wire baskets are simply placed on site and filled with stone. Walls can be extended up or along by wiring the baskets together. Once again, if the height is over a metre approval will be required.

Because there is no cement or mortar used, the structure is not subject to cracking when the soil moves.

Additionally there is no hydrostatic pressure on the wall as the water soaks through the stone. Silt may build up between the stones but this incorporates the basket into the environment and with growth of vegetation can rehabilitate the area.

Furthermore, gabion baskets can be filled with various sizes and shades of stone. This can then be used to make patterns or designs to enhance the appearance of the project.

Basket Range Sandstone Quarry can supply suitable stone for all of the above projects and more, and would be happy to use their expertise and experience to help with your next project.

Basket Range Sandstone has many different options for building retaining and feature walls. Our most popular being a product exclusive to us (and our stockists) the Sawn Wallers which come in 3 different heights 162mm and 80mm which mix together to make a random pattern as well as a 110mm which is good for making a lower wall.

Most councils will allow a retaining wall under 1m to be built without being engineered, but please do check with your local council just to be sure. Another option if you need to retain taller slopes is to split the walls and leave a gap between each retaining wall

Step 1: Design & mudmap your wall

Make sure you have a clear idea of what you want your wall to look like and where it is going. Have a look at our retaining wall gallery to see what you like

Step 2: Order the product or specify to stonemason

We have a list of stonemasons ready to quote up your job and get the ball rolling, otherwise please check out some of our DIY guides to give you a good idea of what is required before you dive in. Give us a call with your total square metres (or length and height of the wall) and our friendly staff will work out how much stone you will need and make up a quote

Step 3: Time to get dirty

Once your stone has been delivered it is time to get to work. One of the most important steps of building a retaining wall is to excavate the site and setup the compacted footing ready. When working with Sawn Wallers or building stone the key is to get the compacted base to be roughly level and then use a mortar mix of sand and cement to lay the first course in. This will make stacking the rest of the stone on top a breeze.

Step 4: Laying the stone

When working with any type of stone it is always best to have bigger, heavier blocks on the bottom for a good stable base. This will make it easier to balance more rocks on top (you may find some thinner blocks remember to put these together to make a stable surface for the rock on top).

Step 5: Sit back and enjoy the view

Now the hard work is done, it is time to relax and take in the beauty of your natural solid stone retaining wall. Don’t be surprised if after your other half sees the final product, more stone may be required (Please keep our stonemasons in mind if you don’t fell like jumping straight back in)